- Constant Mesh Gearbox

Constant mesh gearbox meaning

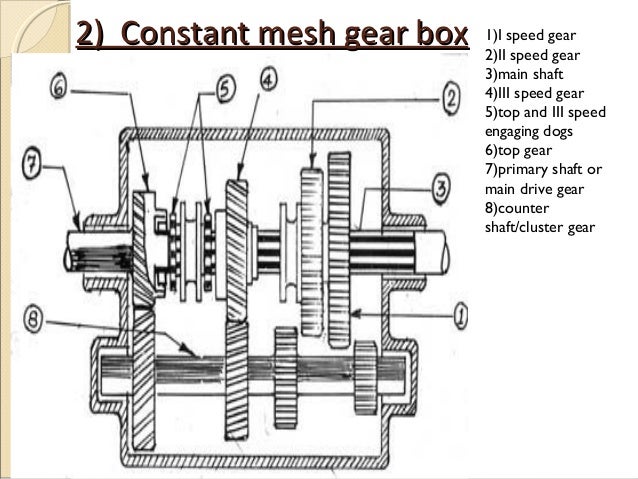

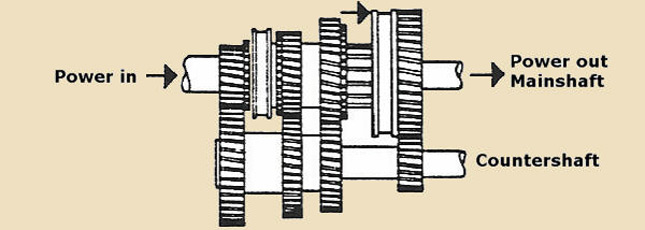

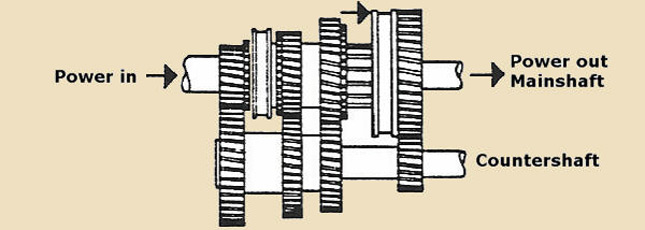

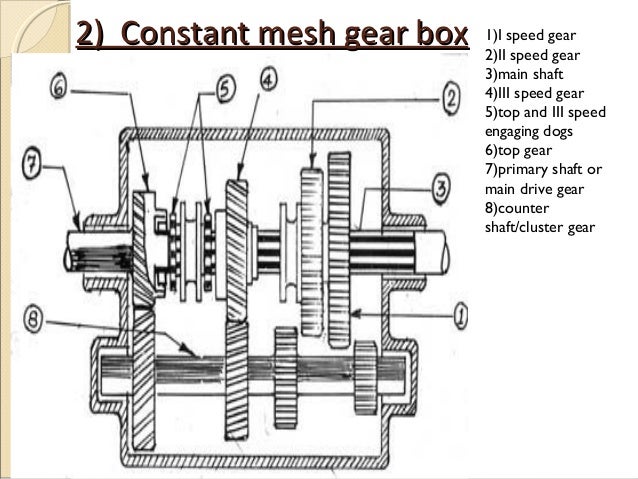

Constant Mesh Gearbox: In a constant mesh gearbox, the gear claws are all arranged on a single file but the order is jumbled up. So for instance the first gear is located at the far end next to the sixth gear and the third gear after that and so on. Constant Mesh Gearbox: In a constant mesh gearbox, the gear claws are all arranged on a single file but the order is jumbled up. So for instance the first gear is located at the far end next to the sixth gear and the third gear after that and so on. The reason behind this is to allow for easy access for the drivetrain accessing the gear cogs on. Constant mesh gearbox definition A type of transmission in which all or most of the gears are always in mesh with one another, as opposed to a sliding-gear transmission, in which engagement is obtained by sliding some of the gears along a shaft into mesh.

Constant mesh gearbox definition

A type of transmission in which all or most of the gears are always in mesh with one another, as opposed to a sliding-gear transmission, in which engagement is obtained by sliding some of the gears along a shaft into mesh. In a constant-mesh manual gearbox, gear ratios are selected by small clutches that connect the various gearsets to their shafts so that power is transmitted through them.

Automotive Dictionary Index

More Automotive Dictionaries

| Author: Bob McCluskey |

| First posted: 1 Sept 2000 |

| Last amended: Dec 2015 |

| Please email Bob McCluskey |

| Car No TD/11935 |

| Engine No XPAG/TD2/12333 |

| Body Type 22381 |

| Body No 11301/78948 |

earbox The synchromesh gearbox was invented by Earl Thompson of General Motors and first appeared on the 1928 Cadillac. MG didn't adopt it for another eight years, so they'd had plenty of time to sort out its bugs. This gearbox is extremely rugged, and apart from the familiar tendency to jump out of third gear (of which more later) I myself have never had a problem. One of my mates once fronted up with an interesting problem: the car was stuck in first gear, and he couldn't change up or down. We found that the anti-rattle spring in the gear lever was broken or weak, and apparently as he drove off in first, the remote control shaft was able to rattle around in its housing, and somehow the selector lever jumped out of its position in the first gear selector, and came to rest in the third gear selector. Now to prevent you from engaging more than one gear at a time, the selector shafts have a tricky little series of interlocking detent balls and cylinders so that only one shaft can be moved at a time. So he couldn't disengage first, because the selector lever was engaged with a different shaft; and he couldn't move that because first gear shaft had already been moved. The side-of-the-road fix was to take off the remote control cover, and disengage first gear by hand; the long-term fix was to fix the anti-rattle spring. For the most part, though, the early systematic problems - like losing the synchromesh balls from the third gear synchro hub - have all been addressed and solved long ago, and what is left is a simple and reliable piece of engineering. Nevertheless people who will cheerfully contemplate a major engine rebuild - even people who can make the fuel pump work properly or set the voltage regulator - tend to go weak and inadequate at the thought of the gearbox with all its little balls and springs and bearings. There is absolutely no need to panic, and unless you're very unlucky you don't need any of the special tools the manual talks about; the gearbox is quite straightforward, indeed the manual deals with it in only 7 pages compared to 14 for the brakes or 15 for the fuel system - and of those seven, one is for a cutaway drawing, one for an exploded diagram, and one for a parts list. The only hard part is getting it out in the first place and to make it easy on myself, I assume here that you've already overcome this challenge. The manual says you should mark the propshaft flanges to ensure reassembly in the same position, but I found that anyway the bolts only allow assembly in one position.

Do all the obvious things like draining the oil, removing the dipstick and filler cap, taking off the rubber rear engine bearing, and removing the speedometer drive housing. Take off the bell housing with the clutch operating lever and carbon thrust washer; the front oil seal will remain in the bellhousing, and you'll want to replace this. Put the gears into neutral, take off the remote gear shift lever and cover, and take out the selector springs with their little balls; unless you're a student of ballistics, don't change gear during this exercise, as these little balls can squeeze out like orange pips and can travel a truly impressive distance when there's no recessed cover to keep them under control. Take off the locking wire from the square-headed screws on the selector shafts, and remove the screws.

Undo the split pin and nut holding the flange, and carefully pull it off. Undo the nuts holding the gearbox rear casing and remove it backwards, taking off the gear selectors from the back of the shafts as it comes off. The rear bearing and guard and felt oil washer will stay in the back of the casing, and the spacer tube will stay on the mainshaft; you might as well take it off now. Take off the circlip from the front of the 3/4 selector shaft, and take the selector shafts out forwards one at a time, lifting off the selector forks as they clear the shafts, and taking care not to lose the little interlock balls which caused my mate so much trouble.

Next thing is to undo the layshaft: undo the locating bolt on the bottom rear of the gearbox, and drive the spindle out towards the rear by driving it out with a soft drift. The layshaft will drop down into the bottom of the gearbox, disengaging the gears and giving room to remove the mainshaft. Gently tap the rear of the mainshaft, and you'll be able to take the first motion shaft (ie, the main drive shaft) with its bearing out through the front of the gearbox; if you're lucky, the needle roller bearings will remain in position inside the first motion shaft, but much more likely they'll fall into the bottom of the gearbox, where they'll be safe for the time being. If you're going to take the bearing off, you need to flatten the tab washer, then undo the nut (which has a left-hand thread) and push off the bearing. On reassembly, make sure you get the bearing guard the right way round - it is concave towards the rear, that is it bears against the inside of the ball-race not the outside.

To get the mainshaft out, you first have to get the mainshaft bearing out. First get the speedo gear off, and if yours is keyed onto the shaft, don't lose the key. Then if necessary tap the mainshaft towards the rear using a drift or piece of dowel until the bearing is driven out far enough to be able to remove it. Now you can simply lift the whole mainshaft assembly out through the top of the gearbox. Lift the layshaft out from the bottom of the box, with the front and rear thrust washers and bearing plates. If you lost any needle roller bearings from the first motion shaft into the bottom of the gearbox, find them now. You don't really need to dismantle the reverse gear mechanism, but if you do, remember it is one of the first things on reassembly.

Digression If you've never seen the gearbox apart before, it might be interesting to consider what happens when you change gear, so first lay the mainshaft on the bench with the first motion shaft, and notice that the 3rd and 2nd gears (the bevel gears) are free to rotate on the main shaft. Now mesh them together with the layshaft, and notice that the bevel gears on 2nd, 3rd and top are continuously engaged; only the square-cut gears on 1st are not engaged. When the first motion shaft is rotated (ie whenever the motor is running with the clutch engaged), it spins the layshaft which turns all the constant mesh syncromesh bevel gears; but because they rotate freely, no torque is transmitted to the mainshaft. Now consider what happens when you declutch and engage, say, top gear.

As you push the gear lever to the right and back, the selector lever moves to the left and away. So it engages the top and third gear selector, which is on the centre selector shaft, and pushes the sliding hub assembly on the splined mainshaft forwards towards the first motion shaft. The bronze synchromesh cone on the inside of the sliding hub pushes against the steel cone on the outside of the top speed gear, and the friction between the two ensures that speeds of the first motion shaft and the sliding hub are matched (because the clutch is disengaged at this time, this means the speed of the first motion shaft is made to match the speed of synchro cone, and because that is splined onto the main drive shaft, it means the first motion shaft is made to match speed of the car; but because the first motion shaft is permanently engaged with the laygear cluster, and it in turn is permanently engaged with 3rd and 2nd gears, it means that all the gears except first have to be accelerated or decelerated to match the first motion shaft, so there is quite a bit of angular momentum to be changed and the synchro hubs have quite a bit of work to do every time you change gear). With a bit more pressure the striking dog overcomes the restraint of the springloaded synchromesh balls, and slides further forward on its splines until its internal splines mesh with the squarecut dog-teeth on the outside of the first motion shaft; the dogteeth on the inside of the striking dog and on the outside of the top speed gear are slightly bevelled to make the entry easier. Now the first motion shaft is locked to the mainshaft through the dog-teeth and the splines on the dog, and the splines on the mainshaft; consequently power is transmitted directly to the mainshaft. Now consider what would happen if you'd engaged third instead. The same sliding hub would slide on its splines towards the back of the gearbox; as before, the bronze synchro cone on the inside of the hub would bear onto the steel cone on the third gear cluster until the speed was matched, and then the striking dog would slide backwards on its splines until its internal splines engaged with the square cut dog-teeth on the third gear. (As with top gear, the dogteeth on the inside of the striking dog and on the outside of the third speed gear are slightly bevelled to make the entry easier, and this turns out to be important from consideration of jumping out of third gear.) Now the third gear is locked to the mainshaft, and power is transmitted through the bevelled constant mesh gear on the first motion shaft, through the layshaft, through the bevelled constant mesh third gear, through the square cut dog-teeth and splines on the dog and through the splines onto the mainshaft. Because the power is transmitted through bevel gears, some of it is resolved into a longitudinal thrust. When power is applied through the engine, the direction of this thrust is to tend to force the third gear assembly forwards along the mainshaft, so third gear engages more securely with the striking dog; but when power is backed off, and the back wheels are pushing the engine, the direction of the thrust is to tend to force the third gear backwards, away from the sliding hub. As far as I can see, this longitudinal thrust is resisted ultimately by the circlip on the mainshaft bearing, which thrusts against the gearbox rear casing: the thrust acts not only on the third speed gear, but on the whole of the mainshaft. For a reason I can't understand, the width of the striking dog was originally barely enough to engage with the dog-teeth while simultaneously covering the synchro balls, and you can perhaps infer that from the drawing. If there is too much tolerance in the gearbox or wear on components, there can sometimes be enough movement in the third gear to allow it to begin to disengage, and if it disengages far enough the bevel on the dogteeth will fling the sliding dog forward and make the gear lever jump violently into neutral: this is the basic reason for jumping out of third on the over-run, and the related problem of synchro balls popping out. To tend to overcome this problem, the width of the striking dog was increased by 2mm (1mm each side) from engine no 20026; if you suffer from the problem, yours is older than that, and you can overcome it by inserting a 50thou (=1.25mm) shim between the circlip behind the 2nd gear sliding hub and the bearing guard in front of the mainshaft bearing, the aim being to limit movement of the third gear by limiting the longitudinal movement of the mainshaft. I am tentatively giving credit for this piece of knowledge to Hugh Pite ; only tentatively because the earliest documented reference I can find is from 2010, whereas I know that this fix was known prior to the car's beginning its long rest in 1976. To give you something to ponder as you roar away in your high-powered sportscar, this implies that the difference between full power and none being transmitted is 1mm of sliding dog!

I was asked a question recently from someone who'd reassembled his gearbox, and was trying it out by turning the main drive shaft by hand before putting it back into the car. He found that while engaging third, sometimes there was so much friction that he couldn't turn the main drive shaft. What was happening is that he was pushing the selector gear further than he should, the third gear synchro was pushing on the third gear, which in turn pushed on the main shaft flange, which pushed on the second gear synchro; so while third was engaged, the second speed synchro was trying to match the speed for second. He solved his immediate problem by remembering to put the circlip on the third gear selector shaft, which limited how far he could push third gear; but, even though he has the later mod with the circlip on third, and therefore presumably also the wider dog, if he doesn't have the jumping out of gear problem, he'll be very lucky.

At much the same time, we were working on an older gearbox, and when it was assembled, but before we put the cover on with the selector balls and springs in place, we did the same thing - changed gears to verify that the gears would select smoothly. Unfortunately without the selector balls and springs, there was nothing limit or define the movement of the selector shafts. It worked well for first and second, but with third the sliding dog slid much further than it should, and uncovered the synchromesh balls. And I can tell you that there can be few sounds so discouraging as the sound of the balls popping out into the gearbox case. But the job went much quicker the second time, and we did peen the balls over in the sliding hub, as described below.

And finally, second gear works almost exactly the same way as top, but with first they did their best to preserve something of the mystique of the old pre-war MGs by keeping the square-cut teeth so we could enjoy the characteristic whine and the art of double-declutching that goes with it.

End of Digression: Back to the task.

The striking dog and sliding hub assembly for 3rd and top slide easily off the splined mainshaft, and to dismantle it further, place it on a bench and simply push the striking dog off the hub. It takes quite a bit of force because the synchromesh balls and springs are located inside the sliding hubs and register against a groove cut internally inside the striking dog. You have to push them out of the groove, and you're doing it without the mechanical advange given by the gear lever. Be careful, because once the dog slides off, unless yours is a late part or has been modified, these balls and springs will feel free to manifest their raison d'etre by springing. In the picture on the left, notice that the synchromesh balls in the sliding hub are retained in place by peening the hub lightly to hold them in place, as described below.

Next the third gear hub. This is free to rotate on the mainshaft on its 32 needle roller bearings, and it's held in position by a collar inside the synchromesh cone. It's not immediately obvious how this collar comes apart, because it's held in place by a spring loaded plunger, and it's easier to consider how it goes together in the first place. The collar is splined internally, and it slides onto the splined mainshaft with the male and female splines aligned. When it's pushed all the way back, the splines are free to rotate in the groove machined in the mainshaft for that purpose. Whenever the male and female splines are aligned, the collar is free to slide off again; but when they're counter-aligned, it is captive, neither the collar not the third gear can come off, but the gear is free to rotate on the mainshaft. To keep the collar in position (to stop it rotating) there is a small spring-loaded plunger in a hole in the mainshaft which engages with a slot in the collar. You can see this plunger from the front, and you simply push it down with a small screwdriver, rotate the collar until the male and female splines are aligned, and slide it off with the third gear. On re-assembly, you can't see the plunger, because the collar is in the way; but there is a small hole in the gear, in the groove between the constant mesh bevel gear and the squarecut dogs, and you rotate the gear until the hole is directly above the plunger, push the plunger down with a piece of wire, slide the collar into position, and rotate it until the plunger engages with the slot. Bingo.

You probably think, like me, that having come up with such a brilliantly simple system for third gear, second gear would be identical. Well Lord Nuffield planned another surprise for us. Behind the collar is a thrust washer, which is not present on the third gear. This thrust washer is in two pieces, and it has two tabs which locate into slots cut into the collar. I find its purpose is hard to fathom: when second gear is rotating freely driven by the layshaft, or when power is applied through second, the longitudinal thrust through the bevel gears is taken by the flange on the mainshaft; on the over-run, the thrust acts to force second gear into closer engagement with the sliding dog, where, I would have thought, the thrust would be taken by the synchromesh cones. Apart from this washer, the collar does come apart the same way, with a spring loaded plunger, and the method described above applies.

On reassembly, first remember the reverse gear if you took it apart. Reassemble the layshaft gear cluster, first the spacer tube and the two washers, one on each end. Fit the needle roller bearings, 14 each end, holding them in place with grease. The manual says you should use a dummy layshaft to hold them in position, but my experience is that you don't need it: once all fourteen are in place, they'll stay there, holding each other in place like the keystone in an arch. Place the thrust washer and bearing plate, remembering that the tabs go uppermost to fit into the bosses in the gearbox housing. When you put the layshaft in position, it will drop to the bottom of the gearbox, where you'll find your fingers won't reach when the mainshaft is in position: put a couple of pieces of string or flexible wire around underneath it first so you can lift it into position later.

Now the mainshaft: first the second gear, with its 28 needle roller bearings, as before packed in grease to hold them in position during assembly, then the two-piece thrust washer, then the plunger with its spring, and finally the collar: remember you have to depress the plunger with a suitable tool in order to assemble the collar, as described above. In the picture on the left I'm fitting the first piece of the two-piece thrust washer, and you can see the second piece on the bench; in the picture on the right I'm using a fine nail punch to depress the plunger.

Now assemble the 1/2 gear sliding hub and striking dog, with the synchromesh balls and springs. The manual says the ball housing openings in the sliding hub are peened over to retain the balls: mine weren't, so I did it myself (of course this means its not original, and I should lose marks at concourse; but in the event it ever goes to concourse, I'm betting that the judges will never find out). Put the spring in position, push the ball down, and using your other two hands lightly peen the hub on two sides of the opening, distorting the metal just enough to stop the ball from popping out (actually, I used a cold chisel, just big enough to bridge the opening, so I could push the ball down and hold it in position with the chisel with one hand while I gently tapped it with a light hammer in the other hand). This is well worth doing (if not already done) because otherwise you have to hold six balls in place against their springs while you slide the dog into place - not easy. Now you can simply push the sliding hub into the dog, using just enough force to overcome the pressure of the balls and springs (do get them the right way round: neither part is symmetrical) and slide the hub onto the mainshaft from the rear (no preferred spline) and fit the circlip and bearing guard.

Now assemble the third gear onto the mainshaft, noting that this time there are 32 needle roller bearings, and remembering how to assemble the retaining collar with its plunger and spring from the discussion above. Assembling the sliding hub and dog is the same as second gear, with just one difference: later gearboxes had an extra ball to locate the sliding hub more securely on the mainshaft. One of the openings in the dog was drilled right through, and an extra ball went under the spring to fit into an indent machined in one of the mainshaft splines. In the picture on the right, you can just see the indent in the mainshaft. If you have this modification, you'll have to fit these two balls and the associated spring from inside the sliding hub, after you have peened over the other holes and assembled the dog. You have to insert the first ball, then the spring, then the second ball, then hold the balls and spring in place while you slide the hub onto the shaft (and of course you have to make sure the assembly goes onto the correct spline on the mainshaft). Not difficult, but a bit tricky. Also remember that the sliding hub is not symmetrical: the flat side goes to the rear, to provide clearance for the retaining collar.

Put the whole mainshaft assembly into the gearbox from the front, the same way you took it out. Put the bearing guard on the back, then the bearing itself, remembering its circlip.

Now the first motion shaft (or main drive shaft): pack the needle rollers with grease, as before, and slide the shaft onto the spigot through the front hole. Put the bearing guard on, remembering that it's concave towards the rear, then the bearing with its circlip. Put on the lock washer, tighten the nut remembering that it's left hand thread, and bend over the lock washer.

The only tricky bit in the whole gearbox is fitting the layshaft gear cluster: the manual passes lightly over this point. Use the wire or string to lift it into position, and push the shaft itself from the back through the centre. The bearing plates with their tabs should still be in position located by the bosses inside the gearbox case, but you may need to fiddle a bit to make the gears engage as the shaft goes in: unless you're very unlucky, in which case you'll have to remove the first motion shaft and mainshaft and do it again, the needle rollers will stay in place, and the layshaft goes easily into position. (Inserting the layshaft is made marginally easier by using a dummy layshaft, cut from an old layshaft to be exactly the length of the the gear cluster; but in fact inserting the layshaft, whether with or without a dummy layshaft, is much easier than getting the gears to engage sufficiently to allow the gear cluster to move into position. Not difficult, but does take a bit of fiddling before all the gears are aligned and the layshaft cluster suddenly slides into position). This is even easier if you can place the gearbox on blocks, front end down: of course the blocks must be just high enough for the main drive shaft to clear the bench, but not so high that it doesn't stay in place. Then you're pulling the lay cluster sideways, not upwards, and when you stop pulling it won't fall back into the bottom of the gearbox. Moreover you can look down the hole where the layshaft itself is going to go, and make sure that everything is aligned, and you can even use a screwdriver (judiciously) to lever the lay cluster into position so the layshaft slides easily into place. Remember to keep the flats on the layshaft on top as it goes in, to accomodate the layshaft screw. When the shaft is more or less at the front of the gearbox, it should be pretty well aligned for the layshaft screw, but you may need to fiddle a bit here too: I found a long thin screwdriver ideal for getting the final alignment. There is a split spring washer on the layshaft screw, but you may want to consider Loctite also.

This is the main part done. Although the first motion shaft and mainshaft are comparatively loose in their places, they can't come out now, and you can work easily on the rest of the gearbox.

Put the selector forks loosely into position, and slide the selector shafts into position from the front, engaging with the forks as they go. I don't think there's a preferred order for this. Don't forget the spacer tube at the front of the 3rd/4th shaft, and don't forget the interlock balls or the little interlock cylinder in the 3/4 shaft. Put the plate guard and the spring plate guard in position behind the mainshaft bearing, and if you have the jumping-out-of-3rd-gear problem, make up a 50thou shim to go behind that. Slide the speedo gear onto the shaft, remembering the Woodruff key if yours is recent enough,then the distance piece tube, the rear bearing with its guard, and finally the felt oil seal if you're going to use it - I had a modification made to allow me to use a modern lip seal.

Now you can offer up the rear casing, sliding the gear selectors onto the selector shaft as it goes up before tightening the six nuts. You might want to think about Loctite here. Tighten the square nuts on the gear selectors and selector forks, not forgetting to wire them. Put the universal joint flange onto the splines, and tighten it up. On early gearboxes, this provided the drive to the speedo gear, by loading up all the components on the back end of the mainshaft - the rear bearing and its guard, the spacer tube, the speedo drive and the mainshaft bearing with its guard, up to the circlip behind the 1/2 gear sliding hub; later gearboxes were modified with a Woodruff key to ensure a positive drive. There is provision for a reversing light switch, but this is blanked off with a plug; if you can find a suitable microswitch you can wire it in, but of course it wouldn't be original.

Reassemble the bellhousing and clutch release mechanism, using a new oil seal. The open side of the oil seal faces towards the oil it is retaining: the drawing in the manual shows the oil seal facing towards the clutch side. I used to think this was because the draftsman was confused by what was then new technology; but of course it's stopping engine oil which has leaked into the clutchhousing past the rear bearing seal from getting into the gearbox.

Now all you have to do is drop the selector balls into position (don't drop them inside, as I have done, because you'll have to take the whole thing apart again), place the springs on top, then fit the gearbox cover.

gearbox flange oil seal modification NSK Bearings 6205VVCMAV2S

As I said, it's easy ...

econd Attempt Well the gearbox worked well enough, but because I hadn't replaced the bearings, it was noisy, and once it did jump out of third. So I resolved that at the first opportunity, I would dismantle it all again, and reassemble with new bearings and with a shim behind the second gear circlip.

Well, pretty soon we had a stroke of luck which gave me the opportunity. After only a few thousand miles, the car began using oil and blowing smoke. Compression on 3 and 4 was unacceptably low, so while the engine was with the engineer (where it stayed for longer than I expected) I used the time to strip the geabox again. Peter and Malcolm came to supervise the reassembly and to offer helpful suggestions, some of which I took. The narrative above still applies, but as well as fitting new bearings, I took the opportunity of modern technology to take some better photos. Some but not all of these are Peter's, but they are my gears, my bearings, and my dirty fingernails, so I felt entitled to use them without further attribution.

| Showing the mainshaft, with the extra detent (from engine no 6533) to give extra security to the 3rd gear sliding hub assembly. Strangely, although my mainshaft and sliding hub both had this mod, the balls in the sliding hub had not been peened over, so I did it myself.. | packing the 3rd gear rollers in vaseline. Also showing the space for the 3rd gear locating plunger | Sliding the 3rd gear speed gear into position over the 32 needle rollers. The plungerand spring must be in position before offering up the gear. |

| Using a fine nail punch to depress the plunger so that the collar can slide into position. | The plunger having been depressed, the collar slides backward into the groove machined for it, then rotated by half a spline. Neither the gear nor the collar can come off now. | The 3/4 sliding hub, showing the balls and springs lightly peened over to simplify assembly (standard from engine no 3114). Also note the bronze internal synchromesh cone. | The striking dog, showing the internal groove to locate the balls and springs in the sliding hub. |

| To assemble the sliding hub, simply push the hub into the dog - no preferred spline. | Slide the hub onto the mainshaft. If you have the detent and the extra ball, obviously you must choose the correct spline. | Now pack the 28 second gear rollers, as before in Vaseline. The two-piece tab washer on the bench beside the mainshaft. |

Second gear assembled onto mainshaft, showing

1) constant mesh bevelled gear 2) dogteeth 3) steel synchro cone 4) locating plunger 5) retaining collar

The tab washer is invisible, hidden behind the collar. |

Mainshaft with 1st/2nd gear sliding hub assembly. The sliding hub is assembled exactly the same way as the 1st/2nd hub, simply pushing the striking dog over the balls in the sliding hub.

|

| 1/2 gear sliding hub assembled onto the mainshaft. The sliding hub is retained by the circlip. Behind the ciirclip is 1) the 1mm shim I made up to mitigate the jumping out of 3rd problem, and 2) the bearing guard, which is not on the 1st motion shaft as the workshop manual believes on pages F4 and F5 | Pack the needle rollers into the layshaft, fourteen each end. Counter to my normal practice, I did use a dummy shaft this time for the reason explained below. | Place the laygear into the bottom of the gearbox, with a couple of bits of string to enable lifting it into position later. Don't forget the thrust washers and bearing plates, remembering also that the tabs go uppermost to fit into the boss. |

| Insert the mainshaft from the front, through the hole in the gearbox case | Slide the mainshaft bearing with its circlip onto the shaft | Press the bearing into its housing |

| Fit the bearing guard and bearing onto the first motion shaft,then the lockwasher and nut, remembering that the nut has a left hand thread, and turn over the lock washer (not shown here) | Pack the spigot needle rollers, as before using Vaseline to hold them in place | Delicately press the first motion shaft into position. It was knowing that the layshaft rollers were unlikely to stay in place through this operation that persuaded me to use a dummy layshaft.In fact we used a pice of dowell, slightly smaller diameter and cut to length, and supplied by Malcolm (thank you, Malcolm) |

| Stand the box on end on blocks, and use the string to pull the lay cluster gears into position. May require a bit of fiddling to get the gears aligned before it slides suddenly into position. | When the gears are aligned, you can look down the hole in the housing and judicially use a screwdriver to get final alignment, when the layshaft will slide easily into position. | As the layshaft slides into position, the dummy layshaft slides out at the bottom. Insert the layshoft locating bolt, and consider use of Loctite. |

| Almost finished now. Put the selector shafts in, from either the front or the rear, and fit the selector shifters as they go in. If you have the circlip on the 3rd shaft, don't forget it. Don't forget the selector lock balls and cylinder, and DON'T DROP THEM INSIDE! Don't forget to wire the square-headed locating screws. | Well, that's it. The speedo gear, the distance piece, the tailshaft bearing and bearing guard have all been placed, and the rear casing offered up and finally bolted into position while placing the gear selectors on their shafts, the square headed bolts have been tightened and locked, and the flange has been done up and wired. The selector balls and springs have been put in position without dropping them, and the gearbox cover fitted. Finally the bellhousing has been fitted. |

Malcolm and I consider our options. Should we have a beer now, or wait a bit longer (delayed gratification being an attribute of high achievers)? |

Constant Mesh Gearbox

please

send me an email

Top of Page